ComfortPlus®

ComfortPlus® belongs to the main family of our materials. It is available in a wide range of densities and colours and can be used to develop solutions for many industrial applications. It is the ideal product to be used in contact with the person, since its main feature is to be transpirable and non-allergenic. Thanks to its softness, it can be used for the protection and presentation of fragile objects.

ComfortPlus® foam

Original price

-

Original price

Original price

-

Current price

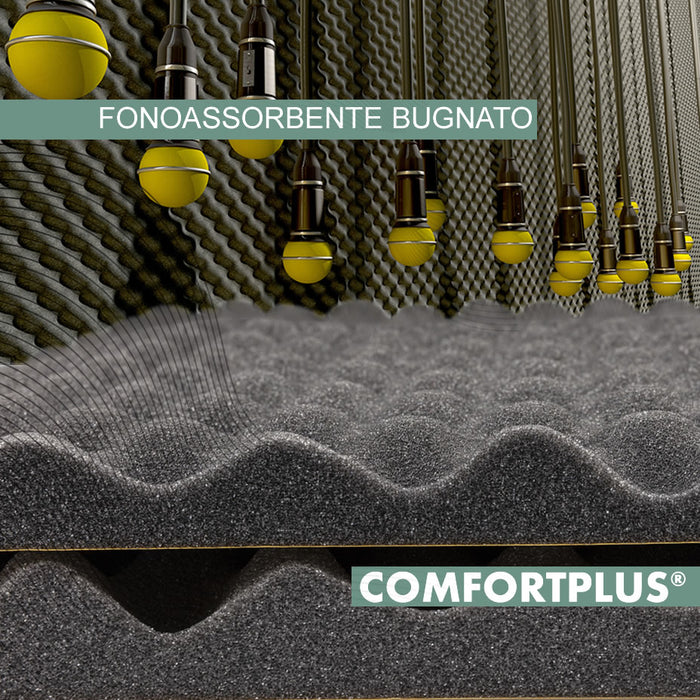

ComfortPlus® 25 mm self-adhesive sound-absorbing convoluted 4 m2

Original price

-

Original price

Original price

-

Current price

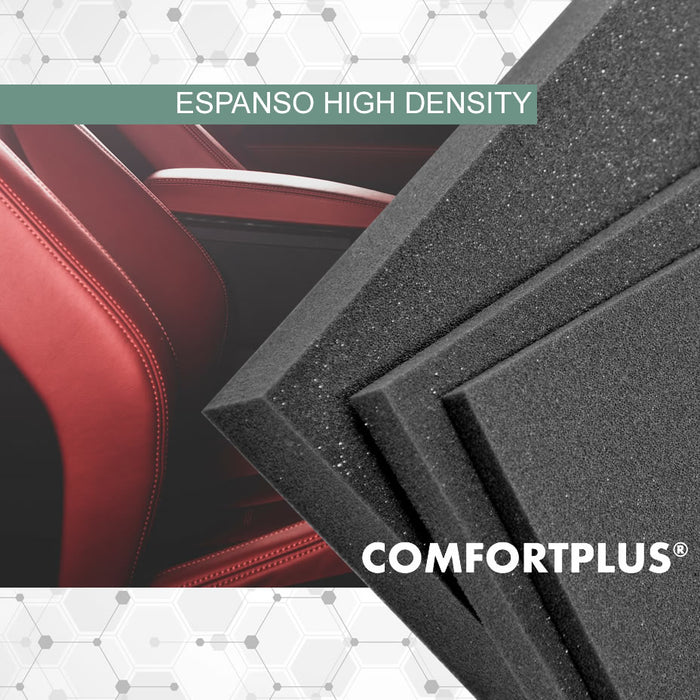

ComfortPlus® HD polyurethane in sheets for orthopedics, sports and technical uses

Original price

-

Original price

Original price

-

Current price